The Professional range of Strautmann trailed diet feeders was developed with the aim of creating a more manoeuvrable and less complex mixer wagon, which is still capable of withstanding the daily demands of TMR feeding across livestock farms.

Alongside a shortened chassis, the simpler three-point weighing system provides accurate, consistent measurements down to the last kilogram.

Professional Range - The new agile and simplified version of the 'Expert' range, with a compact chassis

IMS MIXING AUGER

Variability and strength for any purpose. Due to the patented knife adjustment system and the updated IMS auger design, the IMS mixing auger can be perfectly adapted to your specific conditions of use. The robust and low-maintenance angular gearbox ensures long service life even under challenging conditions.

All Strautmann mixer wagons now come fitted with an IMS auger as standard. Its stepped design enables a good mix to be achieved more quickly.

This reduces the mixing time of each load, which due to the number of mixes each day, creates a saving on labour, wear and fuel over time.

The perfect harmonisation of mixing auger geometry and the distance to the container wall forms the basis for quick and homogeneous mixing.

Robust bearings and gearbox

The heart of the IMS mixing auger is the very heavy duty and durable gearbox. Stability and long maintenance intervals are achieved by means of a large-sized pair of tapered roller bearings, double sealing and a large grease chamber.

Front frame and drawbar

The Professional range of Strautmann diet feeders feature a redesigned, compact front frame and chassis. The single auger machines’ feature a new frame which is welded to the bottom of the body whilst the twin auger machines feature a lighter weight frame, also welded to the bottom of the body. This redesigned frame allows for more manoeuvrability whilst still being able to withstand the demands of livestock feeding.

Enlarged discharge doors

When it comes to discharging the finished ration, 100mm wider (than the Expert model) side doors make for rapid feed discharge.

Weigh cells

Verti-Mix Professional diet feeders are equipped with 3 weigh cells; a single weigh cell on the drawbar and two weight cells between the body and the axle. The three-point weighing system provides accurate, consistent measurements down to the last kilogramme even on rough, uneven terrain.

SPEC-UP YOUR MACHINE

INNODUR stainless steel wear strips

Machinery repair and replacement costs can be reduced by requesting the INNODUR stainless steel wear strip to be fitted to the leading edge of the auger. This is a replaceable part, further extending machine lifetime.

Bale cutting knife

Special knife options help you to adapt your IMS mixing auger to your requirements. Bale cutting knife options available.

Feed funnel

A mineral feed funnel can be mounted at the mixing container on request. This makes it easier to fill in smaller quantities of fodder such as e.g. mineral feed or lime.

Root crop knife

An optional row of cutting knives are available to assist with chopping root crops such as potato and beet.

Protective cover

More safety for your animals.

Protective cover between mixing auger and coaxial gearbox;

- Made of robust plastic

- Recommended for compact mixtures (compact TMR) or for addition of larger quantities of water

- Reliable protection against fodder deposits between mixing auger and gearbox

Magnetic system

Silage and any kind of purchased fodder might contain metallic foreign objects which might harm your cattle. Protect your herds health with the Strautmann magnetic system (optional) mounted directly at the mixing auger protects your valuable livestock against internal injuries.

The magnets are mounted to ensure they have direct and immediate contact with the mixed fodder and offer very effective filtering out of metallic foreign objects without them being carried away again from the magnet by the following fodder.

Enclosed hay ring

Verti-Mix Professional diet feeders come as standard with an enclosed hay ring, however there is the option of having a raised 130mm hay ring (pictured), to suit your requirements.

20mm Heavy-duty mixing auger

15mm mixing augers are standard on all Verti-Mix Professional diet feeders, with a wear material of 10mm. Strautmann also offer a 20mm heavy-duty mixing auger with a wear material of 15mm, for even higher demands.

CONTROL OPTIONS

WEIGHING OPTIONS

PTM HL 50

- 50 rations programmable

- 30 components per ration by name

- Alarm function during loading and unloading

- Programming kg/animal or total weight

- Entry of recipe names and component names

- Large display of component names

- Zeroing / calibration

PTM Advance Super USB

- Programmable weighing device with data transfer. A complete feeding control including time recording is of fundamental importance for cost optimisation on dairy farms.

- 150 recipes from 30 components

- Ration management using software from a remote computer and updated onto the machine using a USB

- Optional: Wireless communication with farm PC

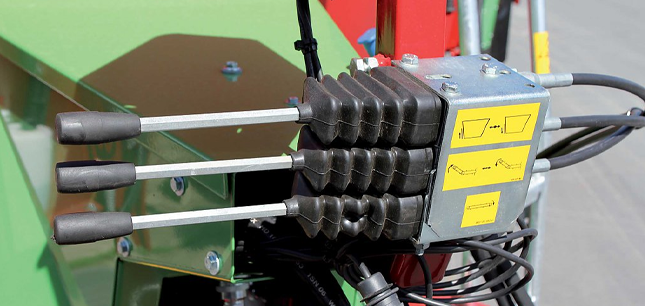

PTM AV 70

Radio remote control

- The PTM AV 70 is a radio remote control to fit:

- HL 50 and Advance Super USB.

- 30 m of range

- Possible installation on the loading vehicle

- Convenient carrying by hand

DISCHARGE OPTIONS

Side Discharge

In the case of side discharge, the asymmetrical position of the discharge openings ensures optimum fodder discharge which results in a loose, homogeneous swathe. The fodder is discharged at the optimum position at the fodder mixing wagon, relative to the flow of material in the container. No travelling over the fodder.

Rear Discharge

Discharge in narrow dead-end feeding passages. For comfortable feeding even in narrow dead-end feeding passages, side doors behind the wheels are being used. The fodder is loosely discharged on one or both sides behind the wheels.

Side Chutes

Fodder-protecting discharge via adjustable side chutes. At the side discharge devices, adjustable chutes support the fodder discharge. The wheels do not roll over the discharged fodder. The side chutes can be equipped with an optional hydraulic actuating mechanism.

Rear Cross Conveyor

Variable conveyor speeds achieved by means of different motors or direct adjustability enable the fodder discharge width to be adapted as far as right up to directly in front of the feed fence. A unique lattice bar roller as return roller for the crossover conveyor prevents the fodder from piling up between the roller and the conveyor.

VERTI-MIX PROFESSIONAL MODELS

Share via WhatsApp

Share via WhatsApp